Rapid Prototyping Automotive Solutions

Rapid prototyping automotive services to help you launch faster, reduce risk, and streamline production cost-effectively.

Why Choose Us?

High-Quality Automotive Parts

As an ISO 9001-certified manufacturer, Huazhi guarantees superior quality in every automotive prototype and part, no matter the design complexity. With our rapid prototyping automotive capabilities, we ensure that all parts are developed to meet global standards using industry-recognized best practices.

Accelerated Turnaround Time

Our seamless blend of cutting-edge technology and skilled professionals allows Huazhi to deliver your automotive components quickly and efficiently. With fast and flexible rapid prototyping automotive services, you can iterate and optimize your products faster—staying ahead of market demands and competitors.

Full Engineering Support

Backed by advanced equipment and deep technical expertise, we offer complete support for your automotive manufacturing projects. From design to finished product, Huazhi’s rapid prototyping automotive solutions ensure every part meets dimensional accuracy, performs reliably, and is production-ready.

Our Awesome Clients

Benefits of prototyping automotive Services

Prototyping Automotive Services offer many benefits including cost savings, increased efficiency, and reduced risk. Prototyping Automotive Services offer a safe and reliable method for developing and testing concepts before committing to full production. By leveraging the latest technologies, Prototyping Automotive Services can develop high-quality parts and prototypes that are precise and reliable.

Prototyping Automotive Services also offer the ability to customize parts and designs. This is especially useful for automakers who want to create a unique look or feel for their vehicles. By working with Prototyping Automotive Services, automakers can customize parts and accessories to their needs.

Prototyping Automotive Services can also manufacture parts for Advanced Driver Assistance Systems (ADAS). By leveraging the latest technologies, Prototype Automotive Services can manufacture reliable and precise parts for ADAS systems such as lane keeping systems, adaptive cruise control, and automatic emergency braking systems.

Advantages of Using Rapid Prototyping to Manufacture Auto Parts

Rapid prototyping redefined the meaning of affordable auto part manufacturing. Receiving custom yet compliant car parts within weeks became achievable since the dawn of this manufacturing process.

Affordable Quality

Rapid prototyping uses the lowest cost of high-quality materials, mainly aluminum and engineering plastics. It can produce repeatable intricate designs for low volume demands. Another good thing is its manufacturing speed, which can only take weeks rather than months for other manufacturing processes.

Easy to Innovate

Car manufacturers can make bridges for mass production after perfecting rapid prototyping designs. In case it doesn’t happen yet, it only needs a lower cost than other processes to make modifications. Revision of CAD models, reprogramming or creating new tooling only takes hours or days rather than weeks or months.

Effective and Efficient Part Design

Several advanced prototyping methods of rapid prototyping include 3D printing, rapid injection molding, or custom CNC machining. In some instances, a single company can use all of these methods to create functional assemblies that vehicles need.

Safety

Automotives have excessive numbers of moving parts. At least one of them failing can pose a high risk of an accident. That is why car manufacturers resort to the most adaptive method to create these parts with the highest quality, rapid prototyping.

What are the advantages of Huazhi

120+

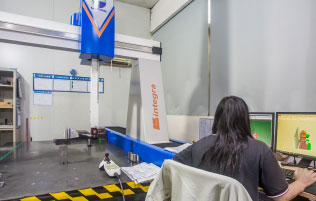

Advanced Equipment

Introduction the world's leading precision machinery, improving manufacturing capabilities, setting standards for precision and excellence, and providing customers with versatile and high-quality production services.

180+

Technical Staff

Our team covers multiple professional fields from engineering to mold design, quality control and project management, creating comprehensive professional technical capabilities to ensure efficient project completion.

20+

Experience

With more than two decades of accumulated expertise and successful cases, we stay ahead in manufacturing innovation and provide customers with consistently high-quality and reliable products.

30+

Served Countries

Huazhi Mould has established a solid business in more than 30 countries, including the United States, Germany, Japan, the United Kingdom and India, and strictly abides by international standards.

What kind of automotive parts can we make?

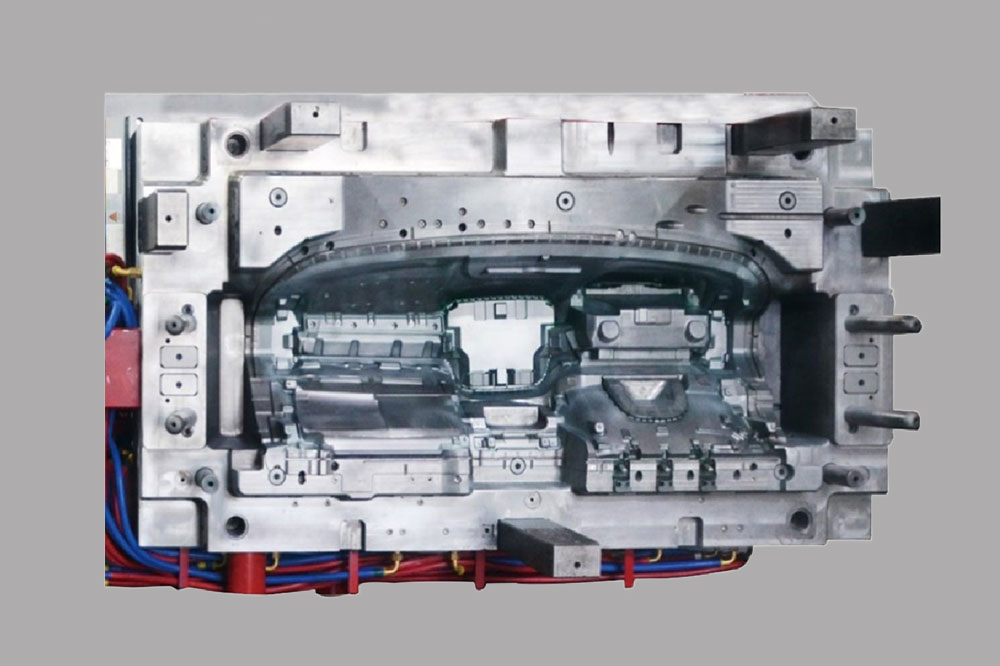

Automobile prototyping plays a crucial role in meeting the demanding needs of the automotive industry, where a wide range of metal and plastic components are required. Automotive clients typically prioritize tight tolerances for critical parts and assemblies, certified wear-resistant materials, and exceptional quality control achieved through in-machine inspection and/or CMM (Coordinate Measuring Machine) verification.

Here are some of the types of auto parts we can produce for you:

Exterior Parts

Bumper

Grille

Fender Flares

Side Skirts

Mirror Housing

Taillamp Housing

Door Handle

Interior Parts

Dashboard

Center Console

Air Vents

Glove Box

Door Trim Panels

Ceiling Lamp Cover

Seatbelt Buckle Cover

Structural Parts

EV Battery Housing

Wiper Motor Cover

Fuse Box Cover

ECU Housing

Connectors

Clips & Fasteners

Cable Brackets

Automotive Electronics Housings

Camera Housing

Radar Housing

Infotainment System Housing

Switch Panels

HVAC Components

Air Ducts

HVAC Unit Housing

Filter Holder

Vents Blades

Engine Compartment Plastics

Engine Cover

Fuel Cap Retainers

Air Filter Housing

Coolant Reservoir

Seat System Components

Side Shield

Adjustment Switch Panel

Seat Back Panel

Mounting Plastic Parts

Chassis Protection Parts

Underbody Shields

Wheel Arch Liners

Radiator Bottom Cover

Find High-Quality Automobile Prototyping Services?

Partner with a trusted expert to reduce lead times and enhance your manufacturing efficiency. Get a free consultation today! Click below to inquire now and let’s create the perfect mold for your needs.

How To Work With Us

The plastic injection molding process may seem simple, but there are many parameters that need to be tightly controlled to ensure the quality and consistency of the plastic components produced.

Submit Your Request

To receive a free quote, simply provide a product description along with a technical drawing. If you don’t have a drawing, don’t worry—we offer reverse engineering services to help you get started.

DFM Analysis & Quotation

We typically respond within 24 hours, providing a Design for Manufacturability (DFM) analysis and a detailed quote. Open communication is key, and we offer unlimited discussions at no cost to ensure the best solution for your project.

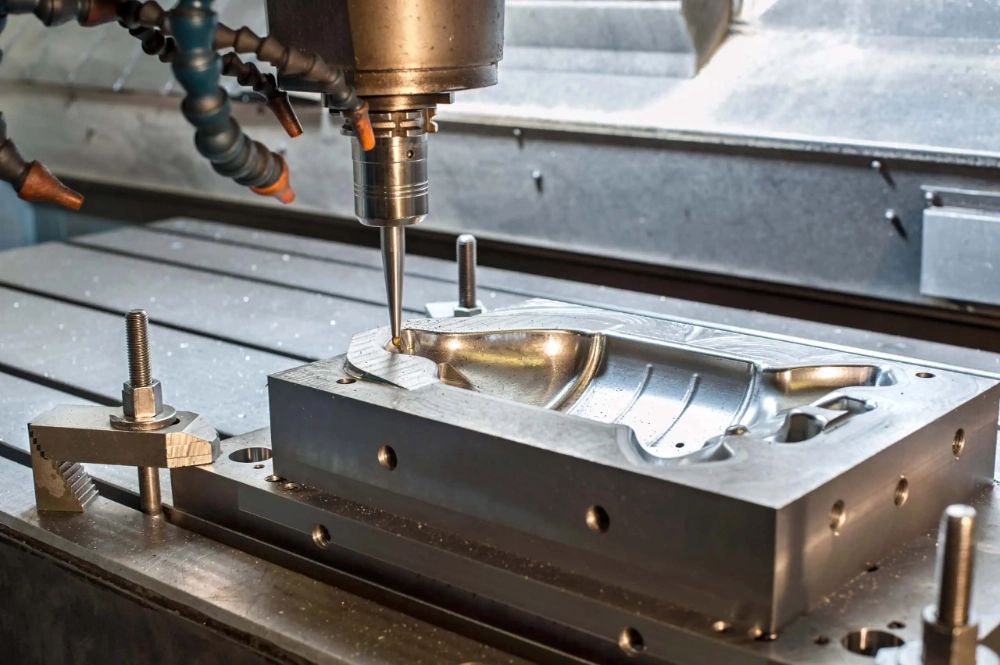

Precision Mold-Making

Once the design is approved, we begin crafting your custom injection mold tooling using state-of-the-art equipment. Our advanced processes ensure a high-precision mold tailored to your exact specifications.

Injection Molding

After mold completion, we initiate the injection molding process, ensuring each plastic part is consistent, durable, and accurate. Our strict quality control measures guarantee optimal performance for every batch produced.

FAQs About Rapid Prototyping Automotive

Rapid prototyping automotive is the process of quickly creating physical or digital models of automotive components or systems to test and evaluate their design, functionality, and performance. This approach helps reduce development time and ensures better decision-making in the early stages of vehicle design.

You can use rapid prototyping automotive technologies to create prototypes for a wide range of parts, including engine components, exhaust systems, suspension parts, exterior and interior trims, and electronic systems. These prototypes support design validation and functional testing.

Absolutely. Rapid prototyping automotive enables designers to quickly build and test multiple design iterations. By evaluating real-world performance and making rapid improvements, you can optimize part quality, meet industry standards, and exceed customer expectations.

Yes. With years of experience in automobile prototyping, we have proudly served top-tier automotive brands such as BMW, Mercedes-Benz, Audi, Honda, Toyota, Cadillac, BYD, and Ford. Our team is equipped to handle complex automotive prototyping projects with precision and speed.

Rapid prototyping automotive is essential in various development stages—from conceptual models and visual mock-ups to functional testing samples. It accelerates product validation, supports design reviews, and improves communication across engineering and marketing teams.

Automobile prototyping involves creating physical models of vehicle components or full-scale assemblies using materials like foam, plastic, metal, or fiberglass. These prototypes help evaluate design aesthetics, ergonomics, and functionality, offering valuable insights before mass production.

Quality

Certifications

Huazhi has many patent certificates and strictly implements international quality control standards in production to ensure product quality. It has passed IATF16949, lSO 9001, lSO4001, lSO45001 certifications.

Related Resources

Get a Free Consultation Now

If you have any questions about your injection mold project, or you are looking for a Chinese injection mold manufacturer, welcome to contact Zhongshan Huazhi for more information. Our experienced engineering team will provide professional advice and solutions for your injection mold project based on your CAD and step drawings.

🚀 Ready to Accelerate Your Automotive Project?

Let Huazhi help you turn ideas into real automotive parts—faster.