Two Color Injection Molding Process – Expert Solutions from Huazhi Technology Since 2006

Introduction

The two color injection molding process is an advanced manufacturing technique that utilizes two different plastic materials to produce a single molded product. This process has revolutionized industries by enhancing product aesthetics, improving functionality, and expanding design possibilities.

Since 2006, Huazhi Technology has specialized in providing innovative and customized plastic injection molding solutions, including two color injection molding. Our extensive experience ensures that clients receive top-quality products tailored to their specific requirements.

Benefits of Adopting the Two Color Injection Molding Process

The two color injection molding process offers numerous advantages over traditional injection molding methods. Key benefits include:

-

Enhanced Aesthetics:

-

With two colors integrated directly into the mold, products achieve a visually appealing finish without additional painting or printing processes.

-

This method is ideal for consumer goods, automotive parts, and electronic devices where visual presentation is crucial.

-

-

Improved Functionality:

-

The process allows manufacturers to combine materials with different properties. For instance, a rigid core can be paired with a soft outer layer for improved grip or comfort.

-

This is commonly used in tool handles, medical devices, and household products.

-

-

Cost Efficiency:

-

By integrating two colors in one molding cycle, manufacturers eliminate the need for secondary processes, reducing labor costs and material waste.

-

-

Greater Design Flexibility:

-

The process accommodates complex geometries and intricate designs, making it perfect for customized components.

-

-

Enhanced Durability:

-

Combining durable core materials with protective outer layers enhances the product’s strength, impact resistance, and longevity.

-

For industries seeking improved aesthetics, durability, and cost-efficiency, the two color injection molding process is a highly effective solution.

How to Achieve the Best Results in Two Color Injection Molding Process

Achieving optimal results with the two color injection molding process requires careful planning and execution. Here are key factors to consider:

-

Material Selection:

-

Choose compatible plastics with similar melting points to ensure proper bonding. For example, pairing polypropylene (PP) with thermoplastic elastomers (TPE) ensures strong adhesion.

-

-

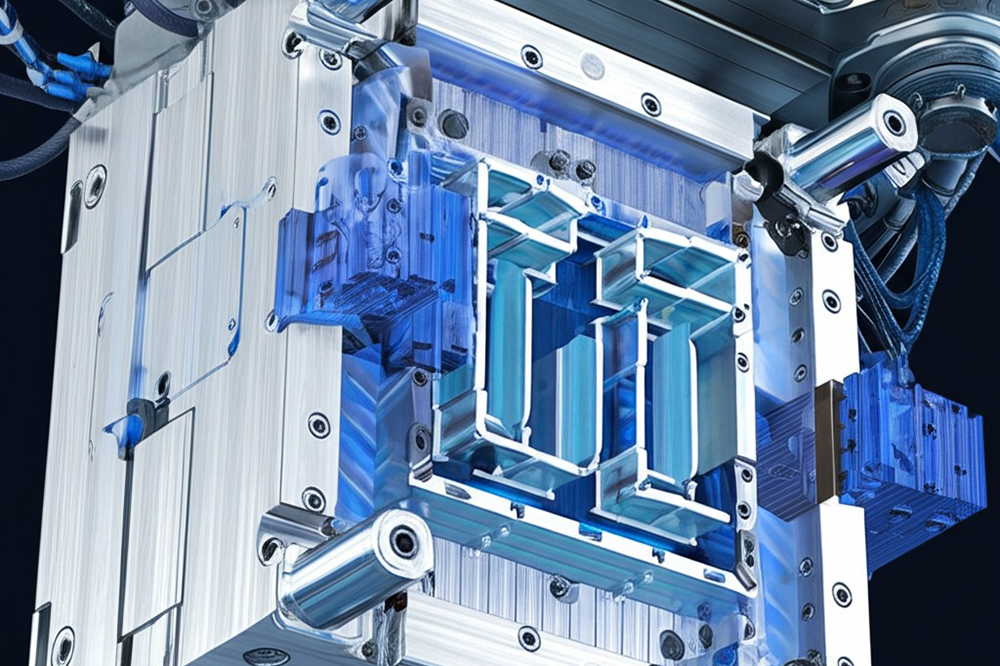

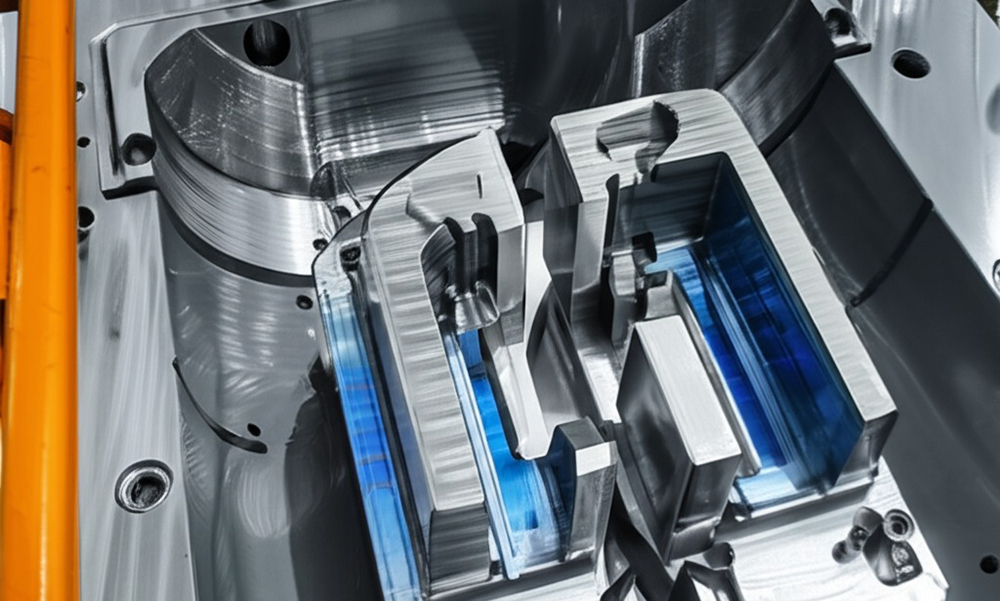

Mold Design:

-

Effective mold design is crucial. The mold should include precise cavity positioning and well-designed gate systems to ensure proper material flow and bonding.

-

-

Injection Sequence:

-

Proper sequencing is essential. The primary material should solidify before the secondary material is injected to prevent defects.

-

-

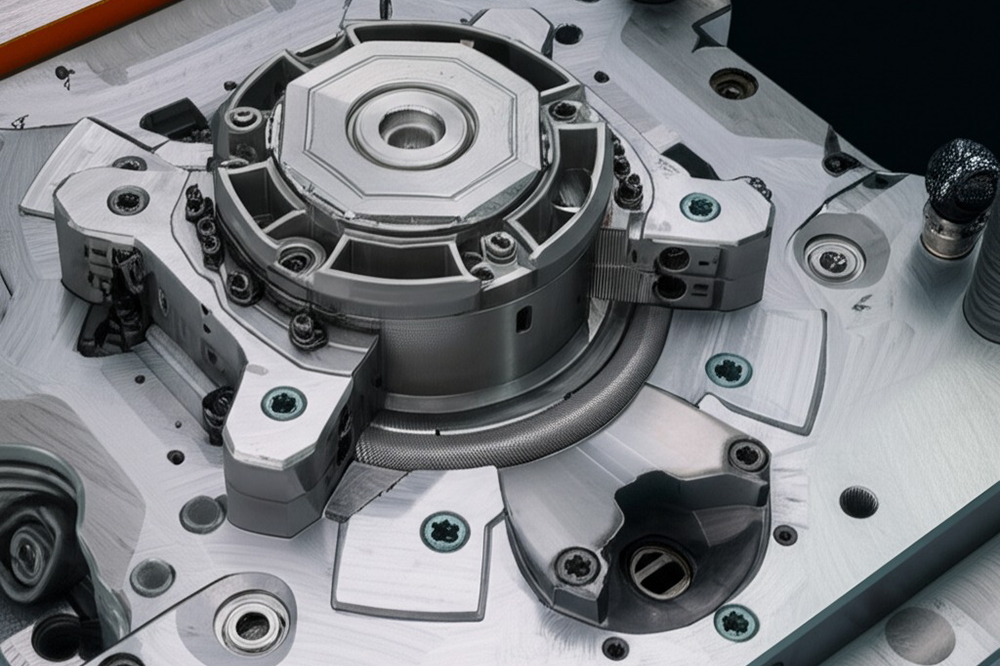

Machine Calibration:

-

Ensuring accurate pressure, temperature, and injection speed control is key to avoiding product warping or deformation.

-

-

Testing and Quality Control:

-

Performing rigorous testing helps identify potential defects early. Techniques like visual inspection, dimensional analysis, and strength testing are essential for quality assurance.

-

By following these best practices, manufacturers can achieve superior results in their two color injection molding process, ensuring high-quality, durable, and visually appealing products.

Key Advantages of the Two Color Injection Molding Process

The two color injection molding process offers unique benefits that make it stand out from traditional molding techniques:

-

Improved Product Appearance:

-

Combining two colors in one mold eliminates the need for painting or printing, providing seamless color integration.

-

-

Cost Savings:

-

Since the entire process is completed in one cycle, labor costs, material waste, and production time are significantly reduced.

-

-

Enhanced Durability:

-

The ability to combine hard and soft materials allows for stronger, longer-lasting products.

-

-

Environmental Benefits:

-

Manufacturers can use recycled core materials in combination with premium outer layers to reduce environmental impact.

-

-

Improved Functionality:

-

Combining different textures or material properties allows for enhanced grip, comfort, or flexibility.

-

-

Versatility:

-

The technique is widely applicable in automotive, consumer electronics, household appliances, and medical devices.

-

These advantages make the two color injection molding process an excellent choice for businesses seeking to enhance product quality and reduce production costs.

Design Essentials for Two Color Injection Molding Process

Designing effective molds for the two color injection molding process requires attention to several critical factors:

-

Cavity Positioning:

-

Ensure that both colors align perfectly by designing precise mold cavities that match the intended product geometry.

-

-

Gate System Optimization:

-

Proper gate positioning ensures uniform material flow and minimizes defects such as flow marks or weld lines.

-

-

Core and Cavity Design:

-

Since two materials are used, the mold’s core and cavity must be designed to accommodate the expansion and cooling properties of each plastic.

-

-

Ejection System:

-

Proper ejection mechanisms prevent deformation during product removal, ensuring consistent quality.

-

By following these design principles, manufacturers can achieve accurate and efficient results with their two color injection molding process.

Comparison Between Two Color Injection Molding Process and Standard Injection Molding

While both methods share some similarities, the two color injection molding process offers distinct advantages:

| Aspect | Two Color Injection Molding | Standard Injection Molding |

|---|---|---|

| Color Integration | Combines two colors/materials in one cycle | Requires additional coloring or painting steps |

| Production Speed | Faster due to fewer post-processing steps | Slower with multiple stages |

| Design Flexibility | Greater design complexity with intricate patterns | Limited design flexibility |

| Material Combination | Allows combining hard and soft materials for improved function | Limited material combinations |

Choosing the two color injection molding process ensures improved aesthetics, efficiency, and functionality compared to standard techniques.

Applications and Future of the Two Color Injection Molding Process

The two color injection molding process has gained popularity across industries, including:

-

Automotive Parts:

-

Producing multi-colored dashboards, switches, and control panels.

-

-

Consumer Electronics:

-

Creating device casings with enhanced grip and durability.

-

-

Medical Devices:

-

Manufacturing ergonomic tools and protective covers.

-

-

Household Products:

-

Designing colorful kitchen tools, toothbrushes, and appliance controls.

-

With advancements in material science and automation, the future of the two color injection molding process promises even greater design capabilities and efficiency improvements.

Why Choose Huazhi Technology for Two Color Injection Molding Process Solutions?

Since 2006, Huazhi Technology has delivered innovative, high-precision mold solutions to clients worldwide. Here’s why you should partner with us:

✅ Extensive Experience: Over 18 years of expertise in two color injection molding.

✅ Advanced Technology: Equipped with state-of-the-art injection molding machinery.

✅ Custom Solutions: Tailored designs to meet specific client needs.

✅ Strict Quality Control: Comprehensive testing ensures product reliability.

✅ Global Service: Serving industries across automotive, electronics, medical, and consumer goods sectors.

For reliable and efficient two color injection molding process solutions, Huazhi Technology is your trusted partner.

Contact Huazhi Technology Today!

Ready to enhance your product quality with the two color injection molding process? Contact Us for customized solutions that meet your design and manufacturing needs.

FAQs

1. What is the two color injection molding process?

The two color injection molding process is a manufacturing method that combines two plastic materials in one molded product, enhancing aesthetics and functionality.

2. What industries benefit most from two color injection molding?

Industries like automotive, consumer electronics, medical devices, and home appliances frequently use this process for improved product quality and performance.

3. What materials are best suited for the two color injection molding process?

Common material combinations include PP + TPE, PC + ABS, and PA + TPE for optimal bonding and durability.

4. How does the two color injection molding process reduce production costs?

By eliminating secondary processes like painting or assembly, manufacturers save time, labor, and materials.

5. Why should I choose Huazhi Technology for my two color injection molding needs?

With over 18 years of expertise, cutting-edge equipment, and customized solutions, Huazhi Technology ensures exceptional results for every project.