CNC Machining vs Injection Molding: Key Differences and How to Choose the Right Process

Introduction

Do you need clarification on the differences between CNC machining vs injection molding? Are you wondering which method best suits your project requirements and specifications? The choice largely depends on your design needs. However, these two manufacturing techniques differ significantly in terms of production efficiency, accuracy, turnaround time, and cost, making the decision difficult.

Additionally, the working principles of CNC machining vs injection molding are completely different. CNC machining removes material using cutting tools to create the desired part, while injection molding involves injecting molten material into a mold that contains the negative geometry of the required shape.

In this article, we will provide an in-depth comparison of CNC machining vs injection molding, discussing their differences, similarities, and applications. By the end, you will better understand which manufacturing process is right for your needs.

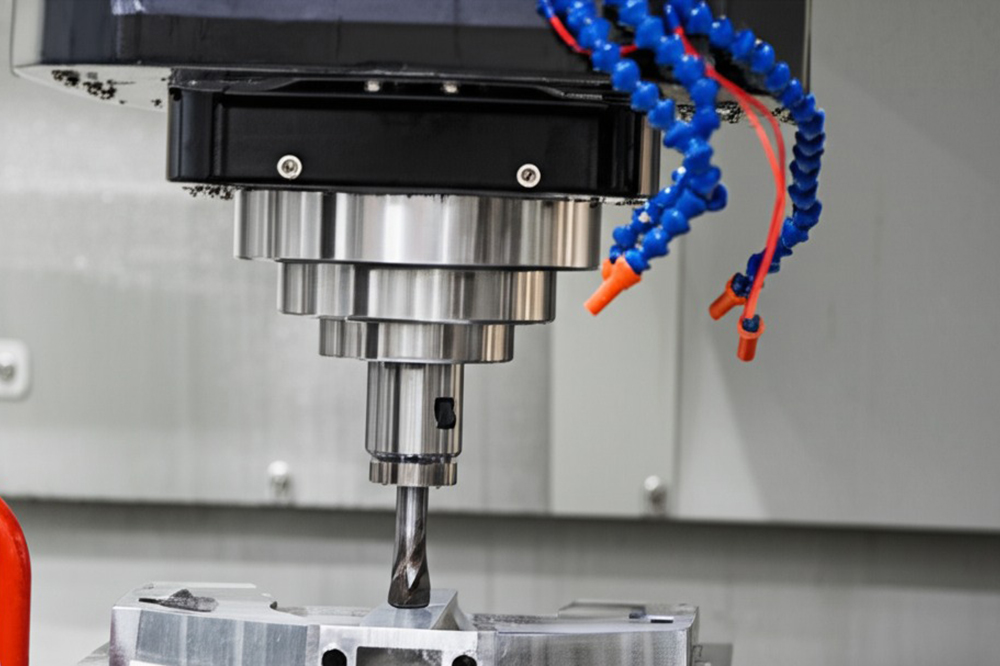

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a solid block using cutting tools controlled by pre-programmed computer software. The CNC system operates in multiple axes (typically three to five), allowing for precise and complex part production.

How CNC Machining Works

-

CAD Design & Programming: The process begins with a 2D or 3D digital design created using CAD (Computer-Aided Design) software. This design serves as the blueprint for the CNC machine.

-

CAM Processing: The design is then converted into a set of instructions using CAM (Computer-Aided Manufacturing) software. These instructions, written in G-code, dictate the movement of the machine’s tools.

-

Material Setup: A workpiece, which can be metal, plastic, or composite material, is securely placed on the CNC machine.

-

Machining Process: The CNC machine removes material layer by layer to form the desired shape using various tools such as drills, end mills, and lathes.

-

Finishing & Quality Control: The machined part may undergo additional surface finishing treatments such as polishing, coating, or anodizing to improve its appearance and durability.

Advantages of CNC Machining

✅ High Precision: CNC machining can achieve extremely tight tolerances, sometimes as precise as ±0.0001 inches, making it ideal for aerospace, medical, and automotive applications.

✅ Versatile Material Options: It is compatible with a wide range of materials, including metals (aluminum, titanium, stainless steel) and plastics (ABS, PEEK, nylon).

✅ Flexibility in Design: Since no mold is required, design modifications can be implemented quickly without additional tooling costs.

✅ Fast Prototyping: CNC machining allows for rapid prototyping, making it a preferred choice for low-volume production and iterative design testing.

Disadvantages of CNC Machining

❌ Higher Cost for Large Production Runs: The per-unit cost remains relatively high compared to injection molding for mass production.

❌ Material Waste: Since CNC machining is a subtractive process, excess material is removed, leading to higher material waste.

❌ Limited Complex Geometry: CNC machines struggle with creating deep cavities and intricate undercuts compared to injection molding.

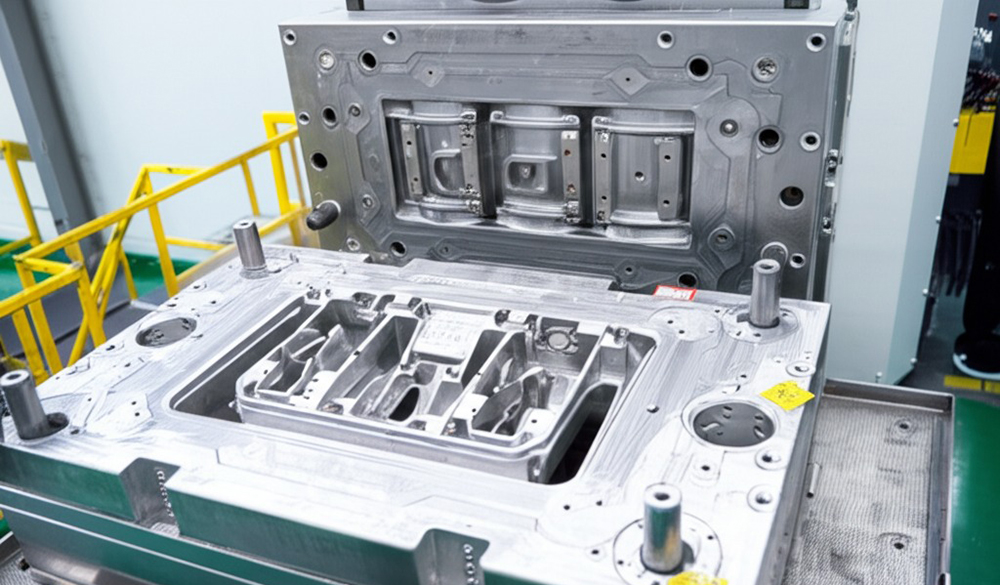

What is Injection Molding?

Injection molding is a mass production technique that involves injecting molten material into a mold cavity under high pressure. Once the material cools and solidifies, the final part is ejected from the mold.

How Injection Molding Works

-

Mold Design & Fabrication: A mold is designed using CAD software and manufactured from hardened steel or aluminum.

-

Material Preparation: Plastic pellets or metal powders are fed into the injection molding machine.

-

Injection & Cooling: The material is heated to a molten state and injected into the mold cavity at high pressure. It then cools and solidifies into the final part shape.

-

Ejection & Finishing: The mold opens, and the part is ejected. Post-processing treatments such as trimming, painting, or coating may be applied.

Advantages of Injection Molding

✅ Highly Cost-Effective for Mass Production: Once the mold is created, injection molding offers low per-unit costs for large production volumes.

✅ Excellent Repeatability & Consistency: Produces identical parts with minimal variation, making it ideal for consumer goods and medical devices.

✅ Supports Complex Geometries: Capable of producing intricate shapes, fine details, and thin-walled components.

✅ Wide Material Selection: Compatible with numerous thermoplastics, thermosetting polymers, and even some metal powders.

Disadvantages of Injection Molding

❌ High Initial Tooling Cost: Mold fabrication is expensive and time-consuming, often requiring several weeks to complete.

❌ Longer Lead Time for New Designs: Design changes require mold modifications, which can be costly and time-intensive.

❌ Limited Material Flexibility: Mostly suited for plastics and specific metals, limiting its use for applications requiring high-strength metals.

CNC Machining vs Injection Molding: Key Differences

| Feature | CNC Machining | Injection Molding |

|---|---|---|

| Material Compatibility | Works with metals, plastics, composites | Mostly plastics, some metal injection molding |

| Tolerance & Precision | High (±0.0001 inches) | Moderate (±0.003 inches) |

| Production Volume | Best for low-to-medium volumes | Best for high-volume production |

| Initial Setup Cost | Low | High (due to mold creation) |

| Lead Time | Faster | Longer due to mold development |

| Part Complexity | Limited by tool accessibility | Excellent for complex geometries |

| Per-Unit Cost | Higher for large runs | Lower for large runs |

When to Choose CNC Machining vs Injection Molding?

-

Choose CNC Machining if:

-

You need high-precision parts with tight tolerances.

-

You are producing prototypes or low-volume batches.

-

You require strong metal components.

-

Your design may require frequent modifications.

-

- Choose Injection Molding if:

-

-

You are producing large quantities of identical parts.

-

You need complex geometries and intricate details.

-

You want a low per-unit cost after initial tooling investment.

-

You are using plastic materials that work well with molding.

-

Why Choose Huazhi for CNC Machining vs Injection Molding?

Huazhi Technology is a leading manufacturer specializing in both CNC machining and injection molding. Our state-of-the-art facilities and experienced engineering team ensure high-quality production tailored to your specific needs.

🔹 Advanced CNC & Injection Molding Capabilities – We use the latest 5-axis CNC machines and high-precision injection molding equipment.

🔹 High-Quality Standards – Our processes comply with ISO 9001:2015 and industry-specific quality certifications.

🔹 Custom Manufacturing Solutions – Whether you need prototyping, small-batch production, or large-scale manufacturing, we provide end-to-end solutions.

🔹 Competitive Pricing & Fast Turnaround – We offer cost-effective solutions without compromising quality.

Conclusion

Both CNC machining vs injection molding offer distinct advantages and applications. CNC machining excels in precision, material versatility, and flexibility, while injection molding is more suitable for large-scale production with lower per-unit costs.

If you are unsure which manufacturing method is right for your project, contact Huazhi today for expert consultation and a free quote!

FAQs: CNC Machining vs Injection Molding

1. Is CNC machining cheaper than injection molding?

It depends on production volume. CNC machining is cost-effective for small runs, while injection molding is more economical for large quantities due to lower per-unit costs.

2. Which process offers better precision?

CNC machining offers tighter tolerances (±0.001 inches), making it ideal for high-precision applications. Injection molding is precise but has slightly larger tolerances.

3. Can I use CNC machining for plastic parts?

Yes! CNC machining supports both metal and plastic materials, offering flexibility in prototyping and low-volume production.

4. How long does it take to produce parts with each method?

CNC machining can produce parts within hours or days, while injection molding takes weeks to months due to mold preparation. However, once molds are ready, production speeds up.

5. What industries use CNC machining vs injection molding?

Both processes are used in automotive, aerospace, medical devices, electronics, and consumer goods. The choice depends on production needs and material requirements.