The Advantages of Huazhi Bumper Injection Molding Services

Ensuring the safety, durability, and design precision of automobile bumpers is critical in the automotive industry. At Huazhi Technology, we specialize in high-quality bumper injection molding services, providing solutions that meet the rigorous demands of vehicle manufacturers and aftermarket suppliers alike. Whether you’re seeking a custom bumper for a new model or a replacement solution, our expertise ensures your needs are met efficiently and effectively.

What is Bumper Injection Molding?

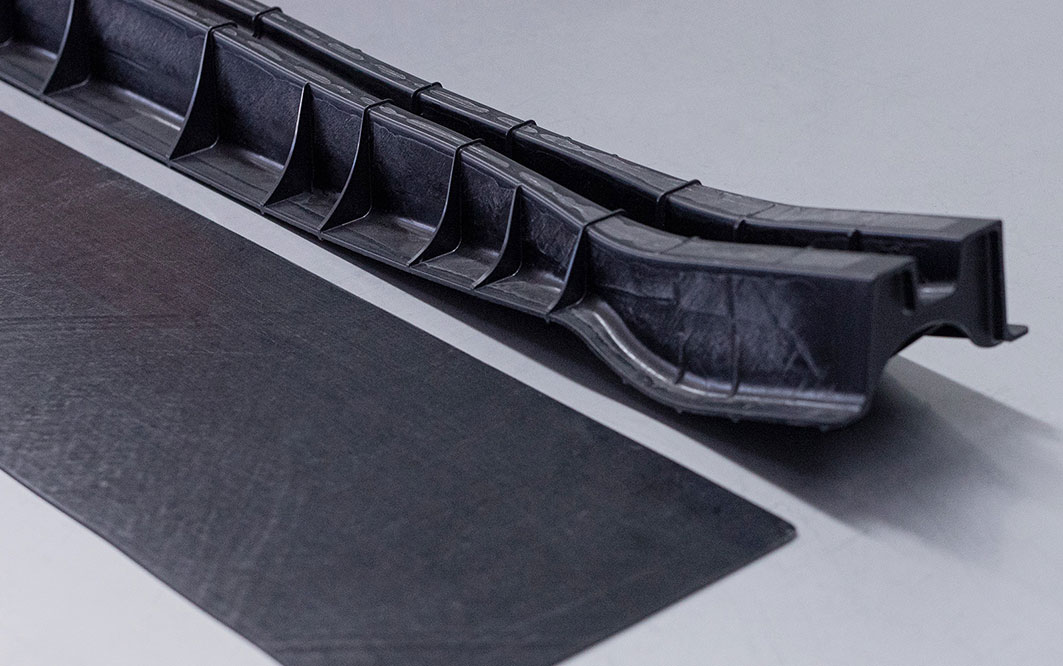

Bumper injection molding is a specialized manufacturing process used to produce durable and precisely shaped automotive bumpers. This method employs plastic injection molding techniques to create bumpers that offer optimal strength and impact resistance.

The Importance of Automotive Bumpers

Automotive bumpers play a critical role in absorbing minor collision impacts, protecting the vehicle’s body, and enhancing overall safety. Modern bumpers are constructed from materials like plastic, polyurethane, and automotive-grade polymers to ensure optimal performance.

How Bumper Injection Molding Works

During the molding process, molten plastic or polyurethane is injected into a pre-designed mold cavity. The material cools and solidifies, forming a precise bumper shape. This method ensures a smooth finish, consistent structure, and enhanced durability. As a result, bumpers produced using injection molding are lightweight yet robust, making them ideal for various vehicles, from passenger cars to heavy-duty trucks.

5 Key Advantages of Our Bumper Injection Molding Services

At Huazhi Technology, we offer premium bumper injection molding solutions designed to deliver exceptional quality at competitive prices. Here are five distinct advantages of partnering with us:

1. High-Quality Materials

We prioritize top-tier materials in our bumper injection molding process. By utilizing premium-grade plastics, polyurethane, and specialized automotive polymers, we ensure each bumper is:

- Impact-resistant: Capable of withstanding minor collisions without compromising structure.

- Lightweight: Reducing overall vehicle weight for improved fuel efficiency.

- Weatherproof: Designed to resist extreme temperatures, UV exposure, and environmental wear.

Our commitment to strict quality control ensures each bumper meets industry standards for strength, durability, and aesthetic appeal.

2. Cost-Effective Solutions

Our streamlined manufacturing process minimizes costs without sacrificing quality. By leveraging advanced injection molding machinery and efficient production techniques, we reduce material waste and optimize cycle times. This allows us to offer:

- Affordable production costs for both low and high-volume orders.

- Budget-friendly solutions for automotive manufacturers and aftermarket suppliers.

- Consistent quality that meets both performance and aesthetic expectations.

Our focus on cost efficiency ensures you receive value-driven solutions tailored to your budget.

3. Customization Options

Every vehicle model has unique bumper design requirements. At Huazhi Technology, we provide fully customizable bumper injection molding services to meet specific client demands. Our capabilities include:

- Custom Shapes and Designs: Achieve distinctive bumper aesthetics that align with your vehicle’s brand identity.

- Size Variations: From compact car bumpers to oversized truck designs, we accommodate diverse size requirements.

- Surface Finishes: Select from smooth, textured, or painted finishes for enhanced visual appeal.

Our expert design team collaborates with clients to develop tailored solutions that exceed expectations.

4. Durability and Longevity

Our bumper injection molding services emphasize durability. Each bumper is engineered to withstand:

- Repeated exposure to temperature fluctuations, UV radiation, and harsh environmental conditions.

- Impact stress from minor collisions and road debris.

- Long-term use without compromising strength or appearance.

By investing in durable bumper solutions, clients reduce the need for frequent replacements, ensuring lasting performance and enhanced cost savings.

5. Fast and Reliable Production

We understand the importance of timely deliveries in the automotive industry. Our efficient production process ensures:

- Rapid Prototyping: Fast-turnaround prototypes for design evaluation.

- Streamlined Production Cycles: Advanced machinery enables faster mold preparation and injection cycles.

- Scalable Solutions: We accommodate both small-batch and large-scale production orders without compromising quality.

Our commitment to meeting deadlines ensures your supply chain remains uninterrupted.

Bumper Injection Molding Process

Our comprehensive bumper injection molding process follows these key stages to deliver top-quality automotive bumpers:

1. Design and Prototyping

We utilize cutting-edge 3D design software to create precise bumper prototypes. This allows clients to visualize the final product before full-scale production. Our design team works closely with clients to refine the prototype and ensure it meets all aesthetic, functional, and performance criteria.

2. Material Selection

Choosing the right material is vital for bumper performance. We offer a selection of high-quality plastics, polyurethane, and automotive polymers, ensuring:

- Strength and Flexibility: For improved impact resistance.

- Environmental Resilience: Protection against heat, cold, and UV damage.

- Cost Efficiency: Materials that balance performance and affordability.

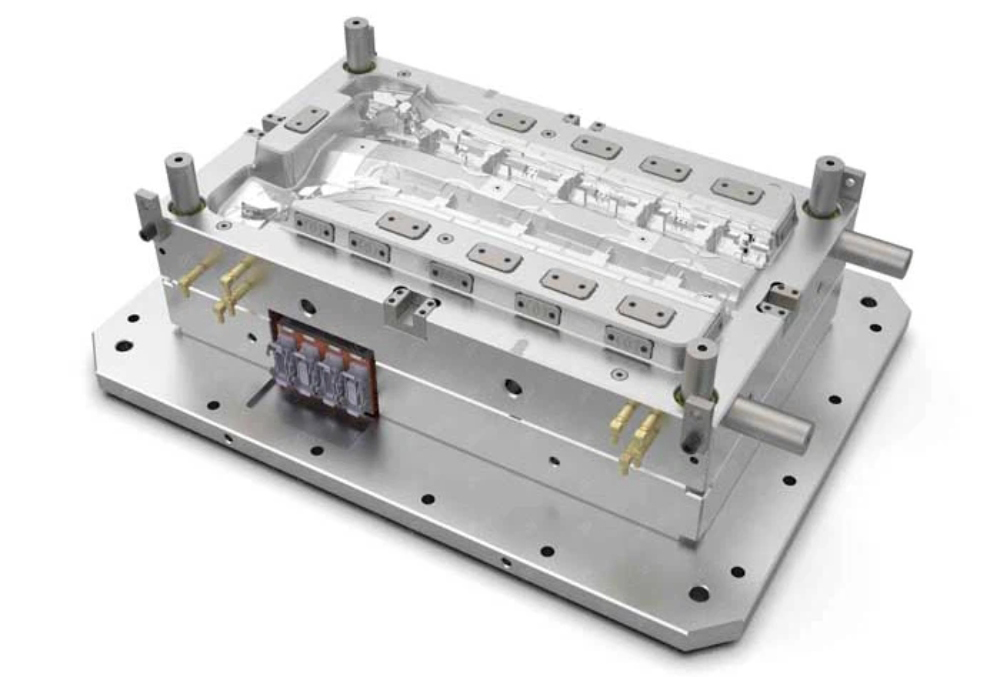

3. Mold Preparation

Precision mold creation is critical for achieving consistent bumper designs. Our state-of-the-art mold preparation equipment ensures each mold is engineered for accuracy, strength, and long-term reliability.

4. Injection Molding

Our advanced injection molding machines efficiently inject molten material into the mold cavity. This process ensures:

- Precise Shaping: Each bumper retains its intended design and structure.

- Consistent Quality: Uniform product thickness, texture, and finish.

- Reduced Waste: Optimized material usage to minimize excess.

5. Cooling and Ejection

Following injection, the bumper cools and solidifies within the mold. Our automated ejection systems carefully remove the finished bumper without damage, ensuring each unit meets quality standards.

6. Finishing and Quality Control

We conduct detailed finishing processes, including trimming excess material, sanding surfaces, and performing visual inspections. Every bumper undergoes strict quality control to ensure:

- Accurate Dimensions

- Durable Construction

- Visual Appeal

Why Choose Huazhi Technology for Bumper Injection Molding?

At Huazhi Technology, we combine decades of experience, state-of-the-art equipment, and dedicated customer service to provide exceptional bumper injection molding solutions. With our expertise in precision mold design, material selection, and efficient production, we deliver bumpers that meet your exact specifications while exceeding industry standards.

Conclusion

Choosing Huazhi Technology for your bumper injection molding needs ensures you receive durable, customizable, and cost-effective solutions. Our commitment to quality, precision, and customer satisfaction sets us apart in the automotive industry.

Looking for reliable and high-performance bumper injection molding services? Contact Huazhi Technology now to discuss your project requirements and receive a customized solution tailored to your needs.

FAQ – Bumper Injection Molding

Q1: What materials are best for bumper injection molding?

A: Automotive-grade plastics, polyurethane, and reinforced polymers offer the best combination of durability, flexibility, and impact resistance.

Q2: How long does the bumper molding process take?

A: Production times vary depending on complexity, but our efficient processes ensure timely delivery without compromising quality.

Q3: Can you create custom bumper designs for unique vehicle models?

A: Absolutely. Our design team specializes in custom solutions tailored to your specific shape, size, and aesthetic requirements.

Q4: What quality control measures are in place for bumper production?

A: Each bumper undergoes rigorous inspection for dimensional accuracy, strength, and finish to ensure optimal performance.

Q5: How can I request a quote for bumper injection molding services?

A: Simply contact our sales team with your project details, and we’ll provide a customized quote tailored to your specifications.