Two Color Plastic Injection Molding vs. Overmolding: What Are the Differences?

Introduction

Injection molding is a cornerstone of modern manufacturing, particularly when it comes to producing high-quality, durable plastic parts for a wide range of industries. Among the techniques that have emerged over recent decades, two color plastic injection molding has become increasingly popular. This specialized process allows manufacturers to produce components with two different colors or materials in a single cycle, offering unmatched design flexibility and efficiency.

In many applications—from automotive interior components to consumer electronics and medical devices—achieving both functional performance and aesthetic appeal is critical. Two color plastic injection molding not only enhances the visual quality of products but also allows for strategic material placement to improve functionality.

However, another popular technique, overmolding, is sometimes confused with two color plastic injection molding. Although both methods involve the use of multiple materials, they differ in process, cost, and application. This article will explore in detail the differences between two color plastic injection molding and overmolding. We will discuss their definitions, working principles, benefits, limitations, and typical applications so that you can choose the method best suited for your project needs.

As you read on, you will gain a comprehensive understanding of these processes, the technical challenges involved, and the factors that should influence your decision-making process. Finally, we will explain why Huazhi Technology is the ideal partner for your injection molding projects. Whether you’re looking to produce automotive components or any other high-performance plastic parts, our expert team is ready to help you optimize your production and achieve superior quality.

What Is Two Color Plastic Injection Molding?

1.1 Definition and Concept

Two color plastic injection molding (also known as multi-shot or dual-shot molding) is a specialized injection molding process in which two distinct plastic materials—or the same material in two different colors—are molded together in a single cycle. This process enables the manufacture of components that incorporate multiple colors or materials seamlessly. Unlike conventional injection molding where a single material fills the mold cavity, two color plastic injection molding involves precise control over the injection sequence and material flow to ensure that the two materials bond correctly.

1.2 Technical Process Overview

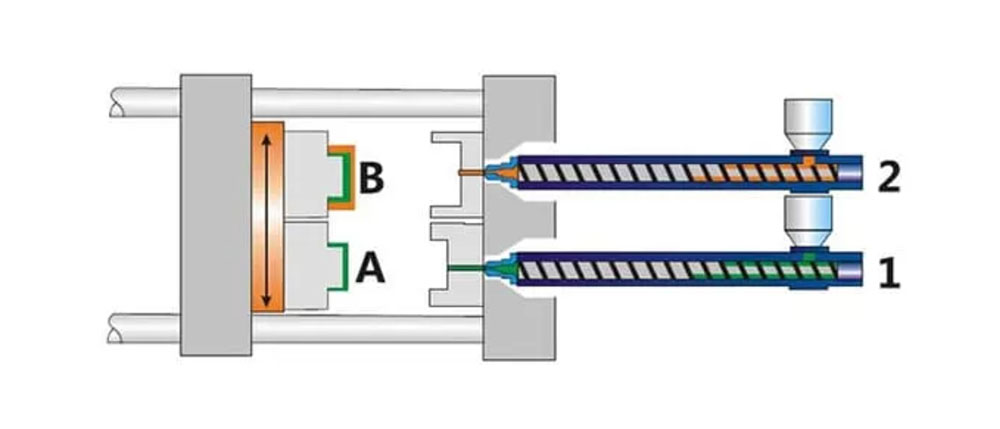

The typical two color plastic injection molding process occurs in two distinct stages:

-

Initial Injection (Base Formation):

-

The process begins with the injection of the first plastic resin into the mold cavity.

-

This first shot forms the base or substrate of the component.

-

Key process parameters such as injection pressure, mold temperature, and cooling time are carefully controlled to ensure a uniform base.

-

-

Mold Rotation/Transfer & Second Injection:

-

After the base material has partially solidified, the mold (or a part of it) rotates or transfers to a secondary cavity.

-

The second resin, which can be of a different color or material, is injected around or over the base.

-

This second shot creates a bond with the base material—often through molecular intermingling—resulting in a single, integrated component.

-

The mold design must ensure proper alignment during transfer to avoid defects and achieve high bonding quality.

-

1.3 Advantages of Two Color Plastic Injection Molding

-

Enhanced Aesthetics:

Allows for complex, multi-colored designs without needing secondary painting or printing processes.

-

Functional Integration:

Enables the integration of materials with different properties (e.g., combining a soft-touch material with a rigid substrate) to improve product ergonomics and functionality.

-

Cost and Time Efficiency:

Reduces overall assembly steps and shortens the production cycle by combining multiple operations into a single cycle.

-

Consistency and Precision:

High repeatability ensures that every molded part meets strict quality standards, crucial for high-volume production.

1.4 Common Applications

Two color plastic injection molding is widely used in industries that demand both form and function. Common applications include:

-

Automotive interior components (e.g., dashboard panels, door trim)

-

Consumer electronics housings with integrated color highlights

-

Medical device components requiring soft-touch features

-

Kitchen appliances and tool handles featuring ergonomically designed grips

The process is highly technical and requires precise control over the injection sequence and mold design to achieve optimal performance. Advances in computer-aided design (CAD) and computer-aided manufacturing (CAM) software have further refined this process, enabling manufacturers to produce highly complex and visually appealing products with remarkable consistency.

What Is Overmolding?

2.1 Definition and Overview

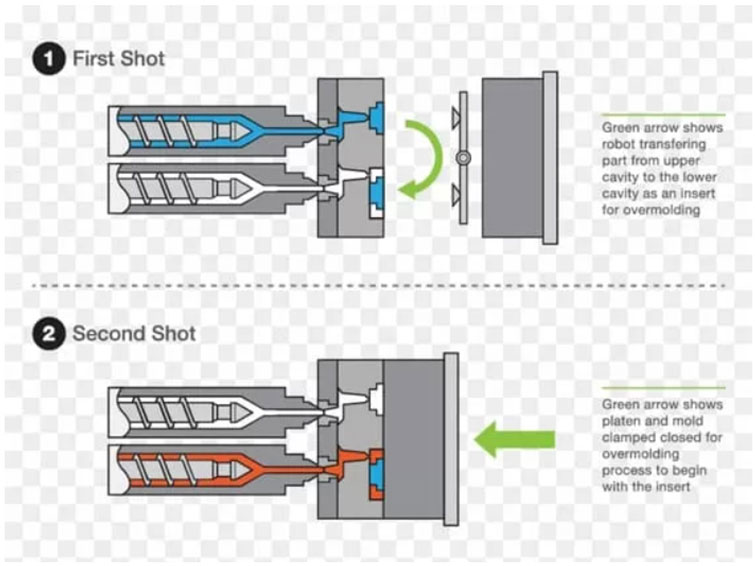

Overmolding is a manufacturing process in which a secondary material is molded over a primary substrate. Unlike two color plastic injection molding, where two materials are injected in sequence within one continuous cycle, overmolding typically involves separate molding steps. During overmolding, the primary part (often rigid) is first created and then placed into another mold where a second material (usually softer) is molded over it.

2.2 Technical Process Steps

-

Substrate Molding:

-

Overmolding Process:

-

The molded substrate is then transferred to a secondary overmolding mold, which has been designed to accommodate both the base and the additional material.

-

The second material, which may be a thermoplastic elastomer (TPE) or another softer polymer, is injected over or around the substrate.

-

Attention must be paid to the bond formation between the substrate and the overmold; this may involve surface treatment or the selection of chemically compatible materials to ensure a strong interlock.

-

2.3 Advantages of Overmolding

-

Improved Ergonomics and Aesthetics:

Overmolding can create parts with soft-touch surfaces that enhance product comfort. For example, tool handles or automotive trim can have a tactile, rubber-like grip.

-

Enhanced Functionality:

Combining a rigid substrate with a flexible overmold can provide improved shock absorption, impact resistance, and durability. This is especially valuable in applications that require both strength and comfort.

-

Simplified Assembly:

By integrating multiple components into a single overmolded part, manufacturers can reduce or eliminate the need for fasteners and adhesives, lowering assembly costs and potential points of failure.

-

Design Versatility:

Overmolding allows designers to incorporate multiple material properties within one component, tailoring performance characteristics such as flexibility, hardness, and thermal stability.

2.4 Applications of Overmolding

Overmolding is employed in several industries for a variety of applications:

-

Automotive:

Overmolded door handles, interior trims, and seals that combine durable structural materials with soft, ergonomic surfaces.

-

Consumer Electronics:

Housings and keypads where tactile feedback is critical.

-

Medical Devices:

Components that require biocompatibility and enhanced user safety.

-

Industrial Equipment:

Grips and controls that need to withstand harsh environments and provide operator comfort.

The overmolding process is particularly favored when product aesthetics and customer touchpoints are of high importance. Its ability to incorporate multiple textures, colors, and functional zones in one component makes it a powerful solution for modern product design.

Pros and Cons: Two Color Plastic Injection Molding vs. Overmolding

3.1 Two Color Plastic Injection Molding: Pros and Cons

Pros:

-

Higher Production Efficiency:

In a single molding cycle, two color plastic injection molding can combine both colors/materials without the need for additional processing steps, resulting in faster cycle times for high-volume production.

-

Superior Bond Strength:

The sequential injection process creates strong molecular bonding between the two materials, ensuring that the final product exhibits excellent structural integrity and durability.

-

Integrated Design Capability:

By using an integrated approach, manufacturers can achieve intricate and precise designs with predictable material flow and consistent aesthetics.

Cons:

-

High Initial Investment:

The complexity of designing and fabricating specialized molds for two color plastic injection molding can result in higher upfront costs.

-

Limited Flexibility for Small Batches:

Although ideal for high production volumes, the process may not be as cost-effective for low-volume or prototype production due to the expense of the molds.

-

Increased Complexity in Mold Design:

Maintaining uniform bonding and ensuring proper material interface requires advanced mold design techniques and precise control over process parameters.

3.2 Overmolding: Pros and Cons

Pros:

-

Lower Upfront Mold Costs:

Overmolding often involves using separate molds for the substrate and the overmold, which can be less expensive to produce for low- and medium-volume applications.

-

Greater Material Flexibility:

The process allows for the combination of vastly different materials, including soft-touch and rigid plastics, which enhances both aesthetics and functionality.

-

Enhanced Ergonomics:

Overmolding is particularly useful for producing components that require a soft-touch feel, such as handles and grips, improving overall user comfort.

Cons:

-

Longer Production Cycle:

Overmolding typically involves two distinct molding steps, which can increase the overall production time compared to two color injection molding.

-

Risk of Poor Bonding:

Ensuring a strong bond between the overmold and the substrate can be challenging, particularly if the materials are not optimally compatible or if process conditions fluctuate.

-

Higher Complexity for Multi-Layer Products:

For parts that require more than two materials or additional layers, the design and execution of the overmolding process become even more complex, raising production risks.

How to Choose Between Two Color Plastic Injection Molding and Overmolding

4.1 Key Considerations in Process Selection

Choosing the right process between two color plastic injection molding and overmolding depends on several critical factors:

-

Production Volume:

-

For high-volume production where consistency and speed are paramount, two color plastic injection molding is generally preferred due to its ability to integrate multiple materials in one rapid cycle.

-

For smaller production runs or when high customization is needed, overmolding offers more flexibility and lower upfront mold costs.

-

-

Design Requirements:

-

If the final part requires a seamless appearance with a strong inter-material bond, two color plastic injection molding is ideal.

-

If the application demands an ergonomic component where a soft-touch surface is critical, overmolding is often the better choice.

-

-

Material Compatibility:

-

Evaluate the chemical and thermal properties of the materials to ensure compatibility during the molding process. Advanced simulation software and trial runs can help predict how materials will bond during the process.

-

-

Cost vs. Performance Trade-Off:

-

Analyze the initial investment in tooling and the expected long-term cost efficiency. Although two color plastic injection molding may have higher setup costs, the per-unit cost can be substantially lower with high-volume production.

-

Overmolding might incur slightly higher cycle times, but lower initial investment and enhanced customization can offset these costs for low- to medium-volume applications.

-

-

Technical Expertise and Process Control:

Consider your internal capability to manage complex mold designs. Suppliers with advanced process control systems and experienced design engineers can mitigate risks and ensure the desired outcomes regardless of the chosen process.

4.2 Making the Decision

Manufacturers should conduct a thorough evaluation, including:

-

Feasibility Studies: Run simulations or pilot projects to test the design and manufacturability of parts with both processes.

-

Cost-Benefit Analysis: Weigh the total investment against production efficiency and the final product quality.

-

Consult with Experts: Engage with experienced injection molding specialists (such as those at Huazhi Technology) who can provide insights and recommendations based on your specific application.

By comparing these factors, companies can decide whether to adopt a two color plastic injection molding process or opt for overmolding based on the demands of their product design and market requirements.

Huazhi: Your Trusted Partner for Plastic Molding Solutions

5.1 Why Choose Huazhi Technology?

At Huazhi Technology, we bring over 15 years of expertise in plastic mold manufacturing. We specialize in both two color plastic injection molding and overmolding techniques, offering a complete range of services from custom mold design to high-volume production.

Our Key Strengths Include:

-

Advanced Manufacturing Technology:

Equipped with state-of-the-art CNC machining systems, 3D simulation tools (such as Moldflow), and automated injection molding machines to achieve high precision and repeatability.

-

Tailored Solutions:

Our experienced engineers work closely with clients to develop customized mold designs that optimize material flow, bond strength, and surface finish. Our expertise covers complex designs that integrate two materials seamlessly.

-

Cost-Effective Production:

We leverage economies of scale and lean manufacturing practices to deliver quality parts at competitive prices. Our integrated approach minimizes waste and reduces cycle times, resulting in lower overall production costs.

-

Quality Assurance:

Strict quality control protocols (ISO 9001:2015 certified) ensure that every molded part meets rigorous industry standards. From dimensional measurements to final surface inspection, our commitment to quality is unwavering.

-

Comprehensive After-Sales Support:

Our team provides technical support, maintenance services, and rapid turnaround on modifications to keep your production running smoothly.

5.2 Customer Success and Reliability

Huazhi Technology has served a diverse range of industries—including automotive, electronics, and medical devices—delivering innovative, durable, and aesthetically superior molded parts. Our reputation as one of the leading gas assist injection molding suppliers extends to our two color plastic injection molding solutions. We help customers overcome the challenges of complex mold designs while reducing costs and cycle times.

Simply understanding the comparison between overmolding and two-color molding may not be enough. Working with a skilled and experienced manufacturing partner like Huazhi will simplify your decision. We have a team of experienced designers, engineers, and machinists. Our team of experts is ready to provide you with full support throughout the entire production process, from design to process selection to final manufacturing.

Huazhi is ready to work with your team to select the right technology for your project. Our injection molding services are ideal for prototyping and production in a wide range of industries. We guarantee fast delivery of high-quality products and offer very competitive prices.

Conclusion

In conclusion, both two color plastic injection molding and overmolding present unique advantages that can significantly enhance product aesthetics, functionality, and cost efficiency. Understanding the technical aspects and limitations of each process is crucial for selecting the best molding technology for your specific application. For high-volume production and projects where seamless color integration is essential, two color plastic injection molding is often the ideal choice. In contrast, overmolding offers a flexible, lower-cost solution for small to medium batch production with a focus on ergonomic and tactile enhancements.

By carefully evaluating factors such as production volume, design complexity, and material compatibility, companies can make informed decisions that optimize their manufacturing processes and improve overall product quality. Huazhi Technology stands ready to support your innovative projects with our state-of-the-art facilities, expert engineering support, and commitment to excellence.

📞 Ready to elevate your product design and efficiency? Contact Huazhi Technology today for a free consultation and quote on your plastic molding projects!

Frequently Asked Questions (FAQ)

Q1: What is Two Color Plastic Injection Molding?

A: It is a process where two different materials or colors are injected sequentially into one mold, enabling the production of multi-colored, multi-material components with excellent bonding and aesthetics.

Q2: What Materials Are Commonly Used?

A: Materials such as ABS, polycarbonate (PC), TPE, and combinations like PC-ABS are common. The selection depends on desired properties like impact resistance, thermal stability, and surface finish.

Q3: What Are the Main Advantages of Two Color Plastic Injection Molding?

A: Key advantages include superior inter-material bonding, reduced secondary assembly costs, high production efficiency, and the ability to create parts with intricate designs and seamless color integration.

Q4: How Does Overmolding Differ from Two Color Injection Molding?

A: Overmolding involves a two-step process where a base part is first molded and then covered with a second material. It offers greater design flexibility for low-volume production but may have higher cycle times compared to two-shot molding.

Q5: What Are the Major Limitations of Each Process?

A: Two color plastic injection molding has higher upfront tooling costs and complexity, while overmolding is typically better suited for lower production volumes and may face challenges with material compatibility and bonding strength.

Q6: Why Should I Choose Huazhi for My Molding Needs?

A: Huazhi Technology offers decades of experience, advanced manufacturing capabilities, and comprehensive support services. We ensure high-quality, cost-effective solutions tailored to your project requirements.