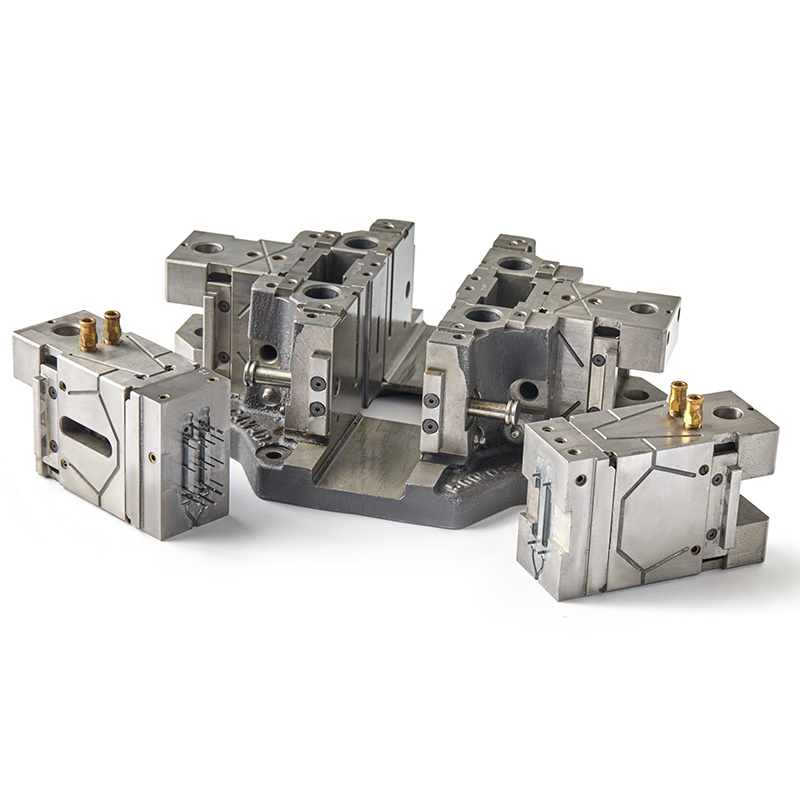

Die Casting Mold Service

Expert in die casting mold design and manufacturing. Huazhi ensures precision casting with fast turnaround and robust problem-solving capabilities.

Why Choose Huazhi for Die Casting Mold Services?

High-Quality Parts

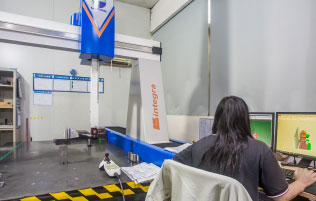

Huazhi, an ISO 9001:2015 certified manufacturer, ensures precision in every die casting mold project. We conduct thorough quality inspections throughout all stages — from pre-production and in-production checks to first article inspection and pre-delivery evaluations — guaranteeing reliable and high-performance parts.

Fast Lead Time

With a robust network of Chinese die casting mold manufacturers, Huazhi ensures efficient production and rapid delivery. Our modern, automated facilities are equipped to handle complex custom projects, providing both speed and precision.

Engineering Support

Specializing in custom die casting mold solutions, Huazhi’s engineering experts focus on enhancing product durability and reducing costs. Using advanced techniques and machinery, we ensure each component achieves optimal quality, functionality, and aesthetics.

Our Awesome Clients

What is Die Cast Mold?

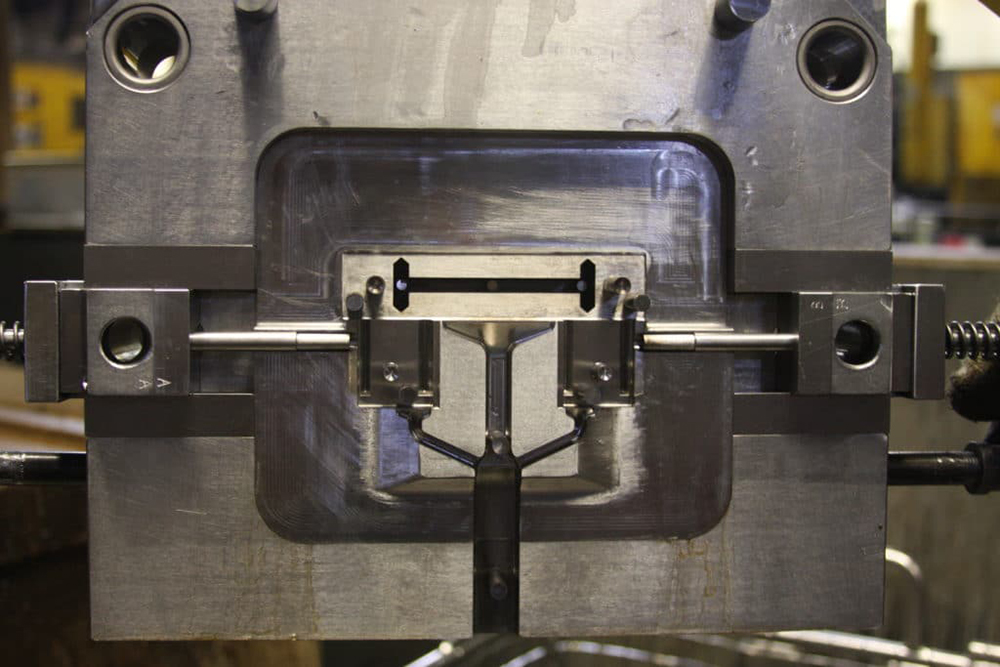

A die cast mold is a tool used to create metal parts by injecting molten metal into a mold cavity. Typically made from hardened steel or aluminum, these molds are reusable and designed to withstand high-pressure injections. This method ensures parts with smooth surface finishes and precise detailing.

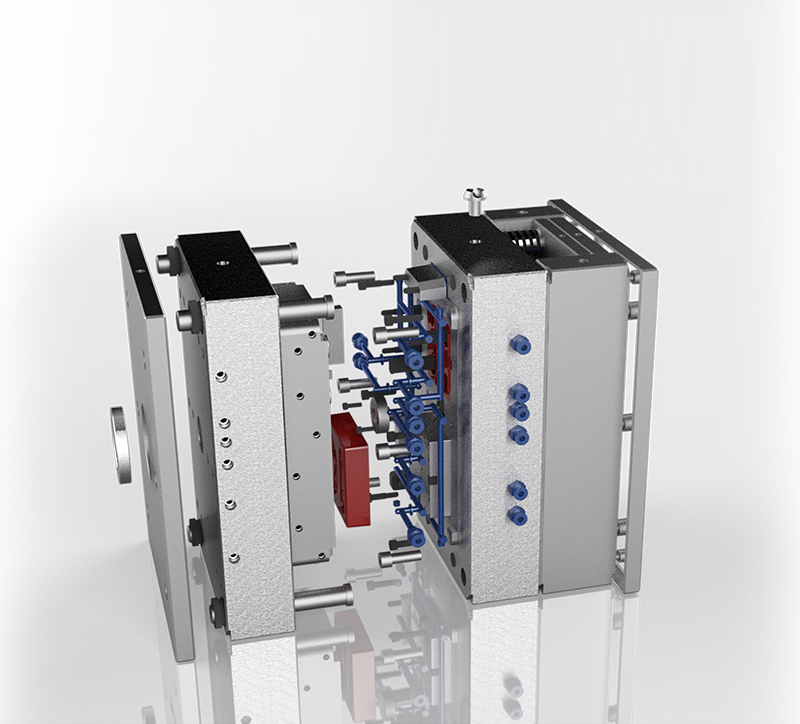

A die cast mold consists of two primary sections — the ejector half and the fixed half — which together shape the dimensions and contours of the cast part. These molds, also called dies, are engineered to meet the exacting standards required for die-cast components.

The die casting process involves injecting molten metal under high pressure into the mold cavity. Molds are designed in multiple parts to facilitate easy removal of the finished piece. Once assembled in the machine, one side remains stationary while the other is movable. The molten metal flows into the cavity and solidifies to form the desired part.

At Huazhi, we excel in developing innovative die cast mold solutions tailored to your project’s specific needs. Our team collaborates closely with you to understand your requirements and deliver precise mold designs that ensure success.

Our versatile capabilities allow us to develop both prototype tools and production molds at cost-effective rates. With rapid lead times and efficient production processes, Huazhi helps accelerate your product’s journey to market.

What are the advantages of Huazhi

120+

Advanced Equipment

Introduction the world's leading precision machinery, improving manufacturing capabilities, setting standards for precision and excellence, and providing customers with versatile and high-quality production services.

180+

Technical Staff

Our team covers multiple professional fields from engineering to mold design, quality control and project management, creating comprehensive professional technical capabilities to ensure efficient project completion.

20+

Experience

With more than two decades of accumulated expertise and successful cases, we stay ahead in manufacturing innovation and provide customers with consistently high-quality and reliable products.

30+

Served Countries

Huazhi Mould has established a solid business in more than 30 countries, including the United States, Germany, Japan, the United Kingdom and India, and strictly abides by international standards.

Find High-Quality China Die Cast Mold Services?

By focusing on advanced casting technologies and utilizing precision die casting machines, we can help you achieve excellence in function and appearance, ultimately increasing the overall value of your product.Partner with a trusted expert to reduce lead times and enhance your manufacturing efficiency. Get a free consultation today! Click below to inquire now and let’s create the perfect mold for your needs.

Advantages and Disadvantages of Die Casting

Advantages of Die Casting

High Precision and Consistency

Die casting excels in achieving tight tolerances and complex geometries with remarkable accuracy, making it ideal for large-scale production of high-quality parts.

Fast Production Cycles

Thanks to the rapid injection of molten metal and swift cooling process, die casting enables quick production cycles, allowing manufacturers to efficiently produce large volumes of components.

Strength and Lightweight Design

Parts produced through die casting feature a dense, fine-grained metal structure formed under high pressure, resulting in strong yet lightweight products.

Minimal Material Waste

Die casting optimizes material usage, generating minimal scrap and reducing the need for secondary processing, ensuring cost-effective and eco-friendly production.

Disadvantages of Die Casting

High initial cost

Due to the large investment in molds and equipment, die casting has high initial investment costs, especially in small batches, and is less cost-effective.

Metal material limitations

The die casting process is mainly suitable for metals with lower melting points. For metals with higher melting points, the casting process is more difficult and less efficient.

Porosity issues

Molten metal may trap air during rapid cooling, resulting in pores inside the part, affecting the overall structural strength.

Size limitations

Die casting is more suitable for the manufacture of small parts. For larger parts, maintaining dimensional accuracy and material uniformity may face certain challenges.

How To Work With Us

The die casting mold process may seem simple, but there are many parameters that need to be tightly controlled to ensure the quality and consistency of the plastic components produced.

Submit Your Request

To receive a free quote, simply provide a product description along with a technical drawing. If you don’t have a drawing, don’t worry—we offer reverse engineering services to help you get started.

DFM Analysis & Quotation

We typically respond within 24 hours, providing a Design for Manufacturability (DFM) analysis and a detailed quote. Open communication is key, and we offer unlimited discussions at no cost to ensure the best solution for your project.

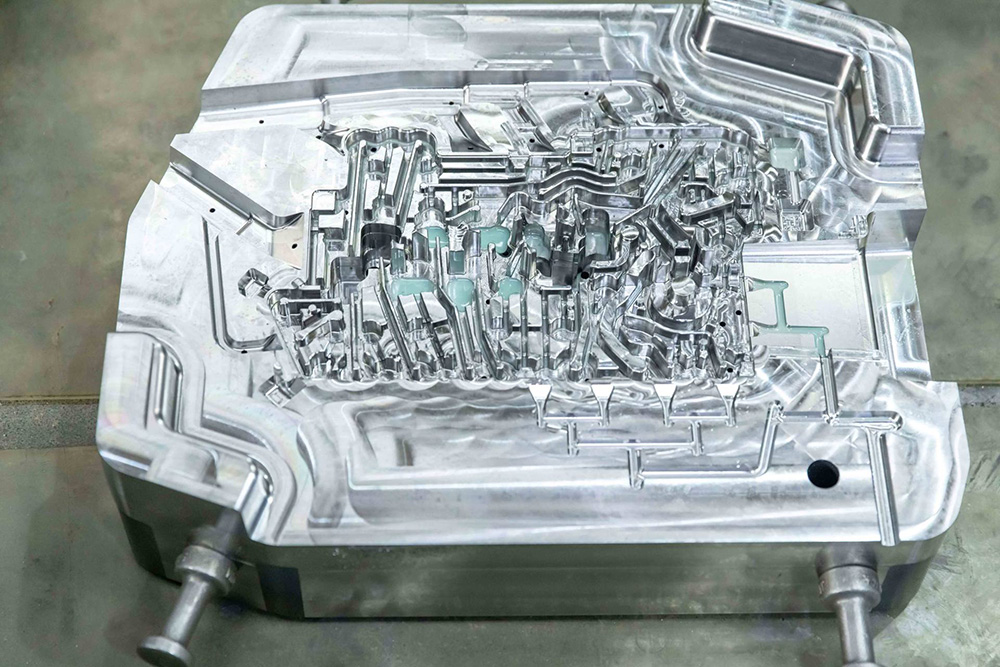

Precision Mold-Making

Once the design is approved, we begin crafting your custom die casting mold using state-of-the-art equipment. Our advanced processes ensure a high-precision mold tailored to your exact specifications.

Die Casting Mold

After mold completion, we initiate the die casting process, ensuring each plastic part is consistent, durable, and accurate. Our strict quality control measures guarantee optimal performance for every batch produced.

FAQs About Die Casting Mold

The die casting mold process involves injecting molten metal under high pressure into a specially designed mold cavity. This mold, known as a “die,” is made from hardened tool steel and functions similarly to an injection mold. The process follows these key steps:

- Mold Preparation: The die is lubricated to control temperature and allow for easy removal of the casting.

- Molten Metal Injection: Molten metal is injected into the die casting mold at high pressure (10 to 175 MPa) until solidification occurs.

- Cooling and Solidification: The metal cools rapidly in the mold, forming the desired part.

- Ejection: Once solidified, the mold opens, and the cast part is ejected.

- Trimming: Excess material, such as gates and runners, is trimmed to achieve the final shape.

To ensure optimal results with your die casting mold, consider the following design tips:

- Wall Thickness: Maintain consistent wall thickness to promote even cooling, reducing defects like warping.

- Draft Angles: Include draft angles (typically 1-2 degrees) to ease part removal from the mold.

- Fillets and Radii: Add smooth curves instead of sharp corners to improve metal flow and reduce stress points.

- Gating System: A well-designed gating system ensures smooth metal flow, reducing turbulence and air entrapment.

- Venting: Proper venting prevents gas buildup, ensuring defect-free castings.

- Simplified Geometry: Reducing complex features minimizes tooling costs and enhances production efficiency.

The die casting mold process is known for achieving precise tolerances, making it ideal for complex, high-volume parts. Standard tolerances include:

- ±0.1 mm for small dimensions under 25 mm

- ±0.5 mm for dimensions up to 250 mm

- ±0.02 mm achievable through post-machining for extremely precise components

Material properties, such as shrinkage rates in aluminum or zinc alloys, influence tolerance outcomes. Advanced techniques like vacuum casting can further improve precision by reducing porosity.

The die casting mold process offers key advantages:

- Complex Shape Production: Ideal for intricate designs with fine details.

- High Precision and Consistency: Ensures uniform parts in high volumes.

- Reduced Post-Processing: Achieves smooth surfaces and precise dimensions with minimal additional machining.

- Fast Production Rates: Efficient for large-scale manufacturing.

Precision die casting is a specialized technique where molten metal is injected into a steel mold under extreme pressure. This method enhances dimensional accuracy, ensuring detailed and uniform parts—perfect for industries demanding high precision.

When selecting a die casting mold supplier, consider these factors:

- Proven experience in producing high-precision castings

- Use of advanced machinery and technologies

- Robust quality control processes

- Comprehensive design support and post-processing services to ensure top-quality results

Quality

Certifications

Huazhi has many patent certificates and strictly implements international quality control standards in production to ensure product quality. It has passed IATF16949, lSO 9001, lSO4001, lSO45001 certifications.

Related Resources

Get a Free Consultation Now

If you have any questions about die casting mold projects, or you are looking for a Chinese die cast mold manufacturers, welcome to contact Zhongshan Huazhi for more information. Our experienced engineering team will provide professional advice and solutions for your die casting mold projects based on your CAD and step drawings.